This article is selected from the technical solution of the parking lot photovoltaic storage and charging integrated project tailored by Brovolt for customers. The solution comprehensively considers the efficient coordinated operation of solar photovoltaic power generation, energy storage system and electric vehicle charging piles, covering the charging pile configuration plan, energy management system (EMS) strategy, economic benefit analysis and project equipment list. The solution aims to maximize the utilization of green energy, reduce peaks and fill valleys, and improve operational efficiency. It is suitable for urban smart transportation and new energy infrastructure construction.

This project plans to install 15 charging piles, featuring a 120kW dual-gun DC integrated machine design, with a total of 30 parking Spaces, which can meet the electricity demand.The demand for high-power and fast charging of automobiles.

The charging pile adopts an intelligent charging module, featuring high power, high efficiency, low harmonics and a high degree of intelligence.According to the charging demand sent by the BMS of the charging vehicle, the charging power is dynamically allocated. When two charging guns are used simultaneously, only one gun outputs.The output power is 60kW. When only one of the two charging guns is in use, the output power of a single gun is 120kW, thereby enhancing the charging equipment.It has a high utilization rate, achieves highly integrated management, has strong scalability, and is energy-saving and efficient.

| Item | Parameter |

Nominal power | 120kW |

| Output voltage | DC 200V~750V |

| Constant power voltage range | DC330V~750V |

| Output current | Max:250A(单枪) |

| Input voltage | AC 380V±15% |

| Input frequency | 50Hz±5Hz |

| Harmonic current limit (THD) | ≤3% |

| Voltage stabilization accuracy | ≤±0.5% |

| Steady current accuracy | ≤±1% |

| Full-load efficiency | ≥95% |

Auxiliary power supply | 12V |

Power factor | 0.9 |

| Operating temperature | -20℃~﹢50℃ |

| Relative Humidity | 5% to 95% no condensation |

| Altitude | <2000m |

| Protection grade | IP54 |

| Installation method | Fixd installation |

| Dimensions | 700W*450D*1600H(mm) |

| Charging interface | 2 |

| Cable length | 5m |

| Human-computer interaction | LED indicator light + 7-inch touch screen |

| Communication interface | CAN、RS485、Enternet、4G(optional) |

| Payment method | Card,Wechat |

| Startup mode | Card , code scanning, VIN code |

| Safety design | Input overvoltage protection, input undervoltage protection, output over-voltage Voltage protection, output overcurrent protection, output short circuit protection, on Door protection, emergency stop protection, over-temperature protection, reverse connection protection |

| Functional design | Power distribution (optional), card swiping control, wechat public account Wechat official accounts and back-end monitoring |

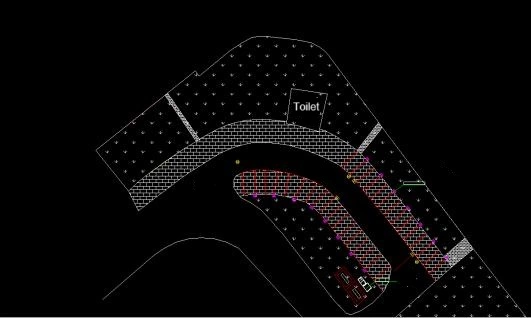

3.1 Site Planning Scheme

The central driving lane of the planned site reserves sufficient space to ensure the normal turnover of vehicles. A total of 30 standard parking Spaces are arranged, with two vehicles each

One charging pile is designed to be installed in the green belt behind the parking space. The battery compartment and equipment compartment are placed in front of the transformer

Square, reserve space for convenient debugging and maintenance.

4. Energy Management System (EMS)

4.1 Introduction to the Energy Management System (EMS

The energy management system (EMS) is integrated into a monitoring cabinet and connected to data such as energy storage PCS, BMS and electricity meters.The internal configuration operation strategy monitors and controls the entire energy storage system, and can communicate with the remote information management system for acceptance dispatch. It has the following characteristics:

1.It has a rich built-in device protocol, dynamically loads devices, and can be connected to various energy storage and microgrid devices.

2.The data mutation upload and master call methods respond quickly and save bandwidth.

3.It is equipped with a built-in flexible operation strategy to support peak shaving and valley filling in the energy storage system.

4.The built-in reports are rich and diverse, and it supports report customization. The data analysis is detailed and in-depth.

5.Alarms, faults and events are pushed in real time or at regular intervals, and all kinds of data records are detailed and accurate.

6.The industrial-grade operation platform ensures a stable, secure and reliable system.

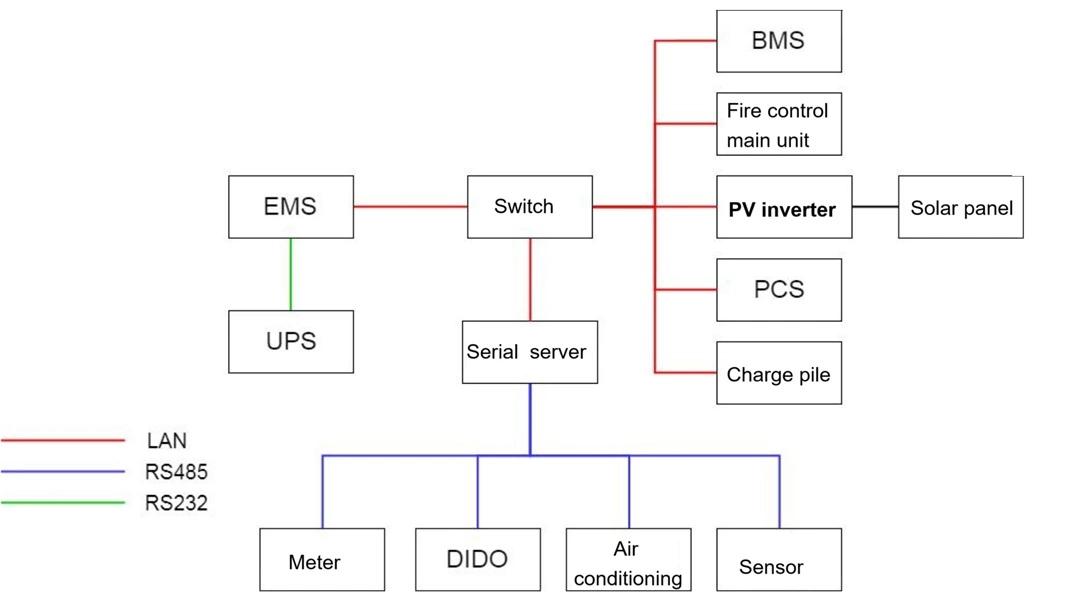

4.2 Topology Diagram of the Energy Management System (EMS)

The energy storage PCS and solar batteries are connected to the switch via network cables and then connected to the EMS. PV system and the charging piles are connected through network cables.Change the machine and then connect it to EMS. Electricity meters, air conditioners, DIDO and other environmental monitoring devices are connected to EMS via RS485. Local customers are accessible.Access and operate EMS through PC access switch.

4.3 Functions of the Energy Management System (EMS)

EMS provides products that meet the monitoring requirements at the plant and station levels in different application scenarios such as storage and charging, and photovoltaic storage and charging. Its main functions include:Home page (Primary electrical diagram), Equipment Management, Alarm Management, Data Analysis, System Settings (User Management, Operation Strategy).

V. Overall Revenue Situation

5.1 Total Project Cost

Based on the current market price, the estimated prices for various photovoltaic projects on the carport roof are as follows: the cost per watt is 6.35 yuan, with an installed capacity of 98.1kW. The estimated initial investment for this project is 6222,935 yuan.

| Item | Capacity | RMB/W | Total Prices |

| Solar panel | 98.1 | 2.41 | 23.64 |

| Inverter | 98.1 | 0.2 | 1.96 |

| Power Distributed Box | 98.1 | 0.33 | 10962 |

| Cable | 98.1 | 0.35 | 3.43 |

| Solar bracket | 98.1 | 0.36 | 3.53 |

| Construction | 98.1 | 0.38 | 2.73 |

| Auxiliary materials | 98.1 | 0.28 | 2.75 |

| Carport bracket | 98.1 | 1.94 | 19 |

| Design | 98.1 | 0.1 | 0.981 |

| Solat battery | 240 | 7.986 | 19 661 |

| Charge pile | 15 pcs | 64000 | 960000 |

Based on the above information, the cost of photovoltaic modules is 236,421 yuan, the cost of carports is 190,314 yuan, and the cost of solar battery is 1,916,640 yuan, and the cost of the charging pile is 960,000 yuan, with a total cost of 3,303,375 yuan.

5.2 Annual maintenance content, costs and insurance costs

The annual maintenance of PV stations is relatively simple, mainly including the following points:

1. Operation status and power generation monitoring. The inverter can display the voltage of the string, real-time power generation, historical power generation statistics, fault alarm and other information, which can be monitored through the mobile phone app.

2. Cleaning of solar panel and line maintenance. Cleaning of solar panels is mainly to remove dust and bird droppings and increase power generation. Rainwater can also play a cleaning role. If there are no special requirements, it is generally cleaned once a quarter or half a year. Line inspection and maintenance can be included in the company's overall regular line maintenance plan.

3. Check the tightness of the clamping bolts every 1-2 years, and tighten the loose bolts.

4. Replacement of damaged photovoltaic modules can be solved by contacting the equipment manufacturer or general contractor according to the contract and warranty agreement. The annual maintenance cost can be calculated according to the owner's arrangement, mainly labor costs. Insurance is mainly to reduce losses caused by natural disasters and accidents. The general enterprise rate is 3%, and more favorable rates may be obtained according to the credit status of the enterprise.

5.3 Overall project revenue

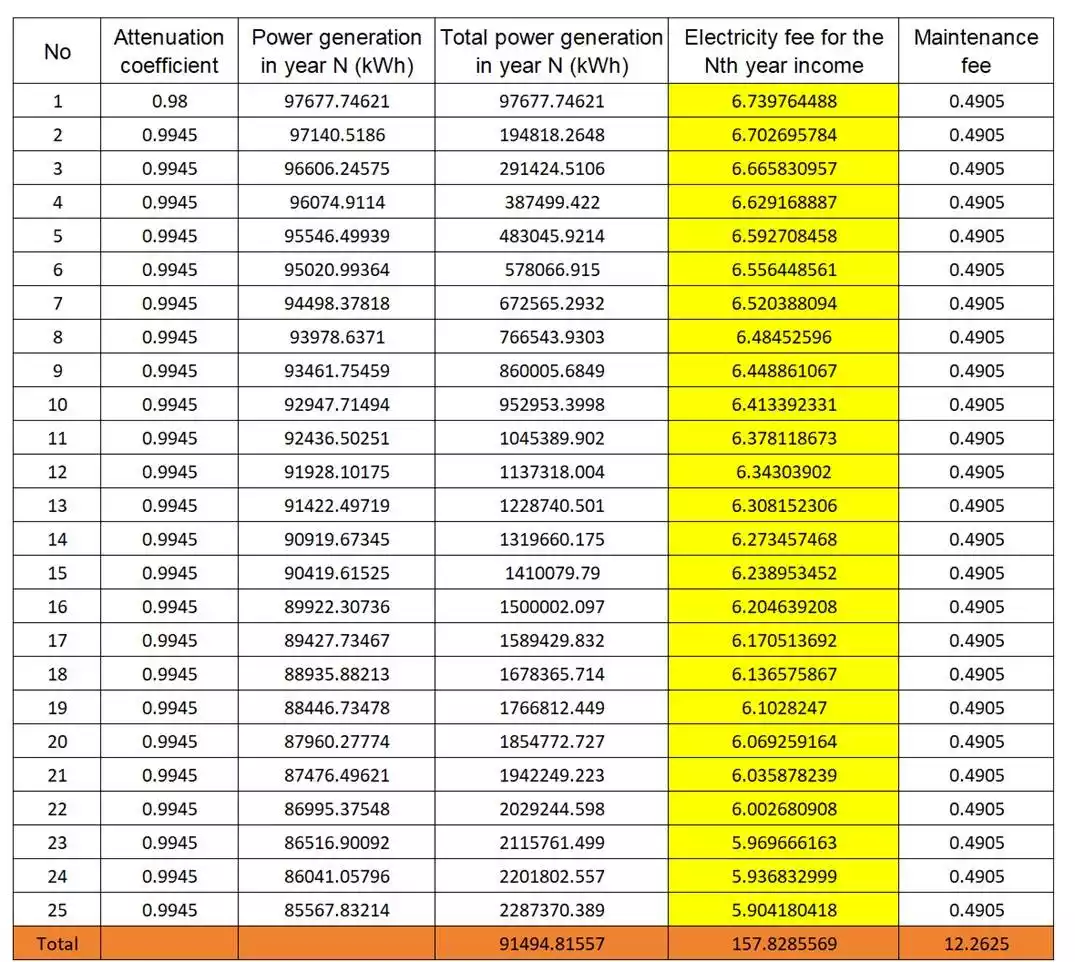

Combined with electricity prices, the annual revenue from photovoltaic power generation for this project is as follows:

PV power generation and revenue

Within the 25-year life cycle of the photovoltaic equipment, the total operating income of the project is 15.78285569 million yuan. Based on the photovoltaic installation price of 6.35/W, the initial investment of the project is 6.22935 million yuan. Excluding the annual maintenance cost of photovoltaic equipment of 0.4905 million yuan. The overall static cost can be recovered in 10.45 years; the dynamic cost can be recovered in 19.90 years, and the after-tax financial internal rate of return is 6.66%. The overall project income is good. From the perspective of the overall project income, the income period is short and the financial internal rate of return is considerable; it relieves the pressure of electricity consumption and increases the implicit income.

VI:Project List

| Item | Name | Specification | Qty |

| 1 | Solar panel | LR5-72HPH-545M | 180 |

| 2 | String PV inverter | 100 kW | 18 |

| 3 | Power distribution cabinet | 1 | |

| 4 | AC cable | ZR-YJV-0.6/1KV | N/A |

| 5 | Carport | High-strength steel frame | 1 |

| 6 | Solar bracket | Aluminum alloy rail bracket | 1 |

| 7 | DC cable | PV1- F1×4mm2 | |

| 8 | PV tray | ||

| 9 | PVC | ||

| 10 | Galvanized flat steel | ||

11 | Design fee | 1 | |

| 12 | Construction fee | 1 | |

| 13 | Hoisting fee | 1 | |

| 14 | Auxiliary materials | 1 | |

| 15 | Pre-installed box | 1 | |

| 16 | Energy storage system | 100kW/240kWh(LiPePO4) | 1 |

| 17 | Charging pile | 120kW | 15 |