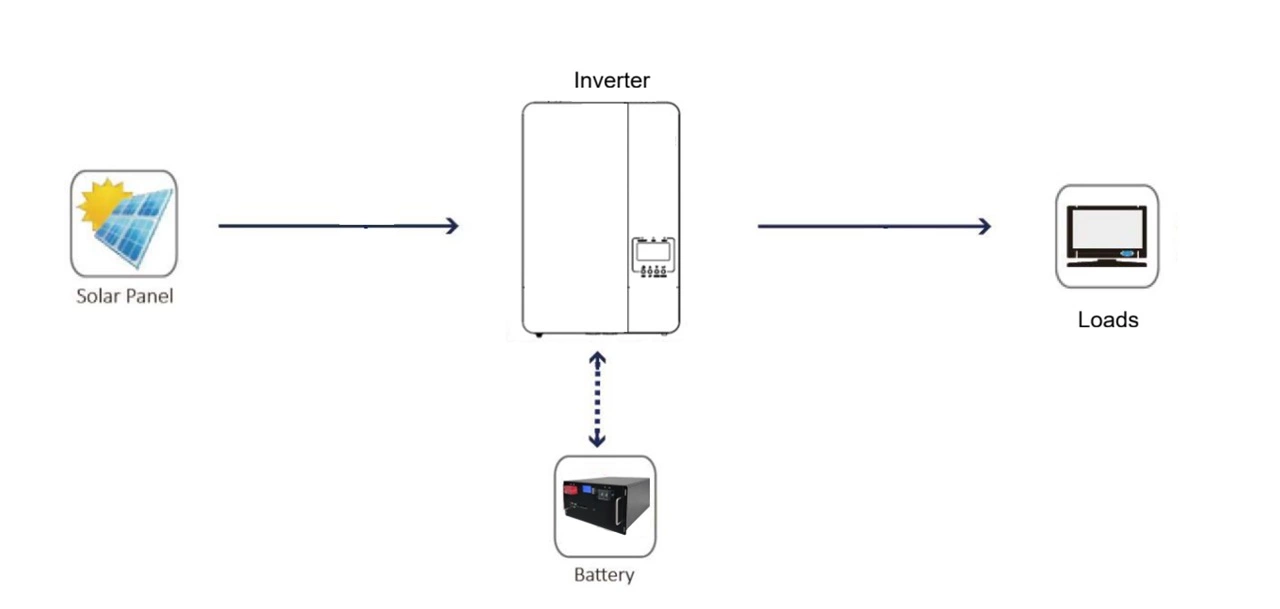

An off-grid photovoltaic (PV) power generation system is an independent energy solution designed for remote villages, households, communication stations, and solar street lighting. The system consists of solar panels, an inverter, lithium battery storage, distribution devices, and cables. Solar modules capture sunlight and convert it into electricity, which is then transformed by the inverter into 220V AC power for daily use. According to clients requirements, Brovolt designed a 4.05kW solar array combined with a 16kWh lithium battery pack, ensuring a reliable energy supply even during continuous rainy days. This system not only guarantees safe and efficient power but also reduces electricity costs, offering users a green, sustainable, and long-lasting clean energy experience.

(1) Background

The roof type is cement roof. The main electrical equipment is a 60W lamp, a 300W TV, and a 350W rice cooker.

(2) Power consumption analysis

The lamp and TV are used for 5 hours a day, and the rice cooker for 2 hours. The daily power consumption is: (60W + 300W) x 5 hours + 350W x 2 h = 2500Wh

3) Solar Power Generation Calculation

According to the customer's requirements, we need to provide three days of power during rainy days. The continuous power provided by photovoltaic power generation during rainy days should reach: (3 + 1) x 2.5 = 10 kWh. Each solar panel power is 450W. Therefore, the installed capacity of this solar power generation system is set at 450 x 9 = 4050W.

The average daily power generation of a 4050W photovoltaic power generation system is approximately 4050 x 2.8 x 0.85 = 10.3 kWh, which is sufficient for three days of normal use.

4) System Introduction

An off-grid photovoltaic power generation system consists of solar panels, an inverter, a battery pack, an AC distribution box, a grounding system, and cables.

PV Array

In the presence of sunlight, solar panels absorb light energy, and the accumulation of opposite charges at both ends generates a "photovoltaic voltage," also known as the "photovoltaic effect." Under the action of the photovoltaic effect, an electromotive force is generated at both ends of the solar cell, converting light energy into electrical energy.

Battery Storage

The function of batteries is to store the energy generated by the solar array and to supply loads at any time. Solar power generation systems require the following battery packs:

1. Low self-discharge rate;

2. Long service life;

3. Deep cycle life;

4. High charging efficiency;

5. Low or no maintenance;

6. Wide operating temperature range;

7. Low price.

According to the guest's requirements, we suggest a 48V314Ah lithium-ion solar battery with a rated capacity of 16kWh as the energy storage system. When the discharge depth reaches 95%, the maximum storage capacity is 15.2 kWh.Brand:Brovolt

Inverter

The inverter integrates MPPT and DC/DC modules. It can control the solar power generation system to charge the battery and simultaneously convert DC power into 220V AC power for user loads.

(5) Advantages of photovoltaic off-grid system

The solar array collects sunlight and converts it into electrical energy. Through control and inverter equipment, the DC power is converted into 220V AC power. Currently, a high-performance lithium solar battery is used as energy storage devices, which can effectively provide owners with continuous power at any time.

Advantages

(1) Develop the value of unobstructed idle roofs and improve the utilization rate of roofs.

(2) Self-sufficiency. The lithium ion solat battery is used as an energy storage device to store the electricity collected by the solar panels during the day for the convenience of owners. In rainy weather, it can provide power for 3 days as required by users.

(3) Long service life, no special maintenance is required. The life of the solar panel is up to 25 years

(4) One-time investment, lifelong benefits, solar energy is clean, radiation-free, and pollution-free.

(5) Green energy, safe and environmentally friendly. Provides clean energy.

III) System Overview

1. Project Name: 4050W Household Rooftop Photovoltaic Power Generation System

2. Project Location: 2213°-23°33°N, 107°45°-108°52°E

3. Climate: Humid subtropical monsoon climate, with abundant sunshine, abundant rainfall, little frost and no snow, mild weather, long summers and short winters, and an average annual temperature of around 21.6°C. Annual sunshine hours are 1478.2 hours, and annual solar radiation per square meter is 4934.8 megajoules. This system has excellent potential for development and utilization of photovoltaic power generation.

4. Roof Area Occupied: Approximately 28 square meters

6. Installed Capacity: 4050W

7. Solar Modules: 9 450Wp monocrystalline silicon modules

8. Installation Period: 2 days

9. Brief Description: Nine 450Wp polycrystalline silicon modules are installed in series on the user's roof, along with one inverter, for an installed capacity of 4050W. The power generated by photovoltaics is first supplied to the load, and the excess power is charged into the battery. When it is cloudy or at night, the battery starts to supply power to the load.

IV) Solar Mounting System

1. Conventional "Deflector Bracket" Installation Method

The "deflector bracket" installation method uses cement counterweights combined with aluminum alloy clamps to secure the deflector at the bottom of the assembly. The assembly is arranged on the bracket and secured with the clamps. See the figure below.

(5) Photovoltaic modules

| Maximum Power - Pmax [Wp] | 450 |

| Maximum Power Voltage - Vmp [V] | 30.04 |

| Maximum Power Current - Imp [A] | 14.98 |

| Open-circuit Voltage - Voc [V] | 35.91 |

| Short-circuit Current - Isc [A] | 15.73 |

| Module Efficiency STC [%] | 22.52 |

| Power Tolerance | 0 ~ + 3 % |

| Temperature Coefficient of Pmax | -0.29 %/°C |

| Temperature Coefficient of Voc | -0.25 %/°C |

| Temperature Coefficient of Isc | 0.045 %/°C |

(6) Off-grid inverter

| Rated power | 3000W |

| Output volltage | 230VAC ± 5% @ 50/60Hz |

| Surge power | 6000W |

| Maximum PV array power | 4500W |

| Startup voltage | 150V |

| MPPT operating voltage | 120VDC ~ 430VDC |

| Maximum solar charge current | 80A |

| Battery voltage | 48VDC |

| Battery type | Lithium ion battery |

| Protection rate | IP20 |

| Dimension (W/H/D) | 330/485/135mm |

| Weight | 11.5kg |

| Humidity | 5% to 95% Relative Humidity(Non-condensing) |

| Operating temperature | 0°C 55°C |

(6) Lithium ion solar battery

| Brand | Brovolt |

| Battey type | LiFePO4 |

| Voltage | 51.2V |

| Capacity | 314Ah |

| Discharge-cut-off voltage | 44V |

| Charge voltage | 57.6V |

| Maximium discharge current | 150A |

| Maximium charge current | 150A |

| Weight | 120kg |

| Dimension | 722*444*233mm |

II. Return on investment and benefits

(I) Power generation and return on investment

The annual average total radiation is 4975MJ/㎡, equivalent to 3.76kWh/㎡·d.

The annual sunshine hours are 1500-1873.7 hours. The total installed capacity of this project is 4050Wp, the average daily power generation is 10.3 kWh, and the annual power generation is about 3769 kWh.

(1) Return on investment: The investment capital of this project is 18,000 RMB. Based on the Nanning residential electricity price of 0.588 RMB/kWh, plus the national subsidy of 0.42 RMB/kWh for distributed power, that is, a subsidy of 1.008 RMB per kWh, the cost will be recovered in about 5 years. The power station will operate for 25 years and the power station will earn 69,225 RMB.

(II) Demonstration Benefits

Solar power generation stations are the process of converting solar energy into electrical energy. During the entire process, no pollutants such as gas, liquid, and solid waste are generated, nor is there significant noise pollution. They have significant energy-saving and environmental benefits.

(1) Develop the value of unobstructed idle roofs and improve the utilization rate of roofs. At the same time, the "insulation layer" on the roof formed after the photovoltaic modules are laid reduces the average indoor temperature; the laying of solar panel on the roof directly blocks the erosion of the building from the sun and rain, increasing the service life of the building.

(2) Effectively utilize solar energy and provide electricity to nearby users, which can effectively provide owners with continuous electricity at any time, saving users a large amount of electricity expenses.

(3) The construction of the power station has an ecological and environmentally friendly landscape, provides clean energy, and has a good demonstration effect.

3. Operation and Maintenance

In order to ensure the safe and stable operation of the system, the solar power generation system needs to be maintained regularly.

(I) Photovoltaic array

1. The operation and maintenance of photovoltaic modules shall comply with the following regulations: The surface of photovoltaic modules shall be kept clean. When cleaning photovoltaic modules, attention should be paid to the following:

(1) Use a dry or damp soft and clean cloth to wipe the photovoltaic modules. It is strictly forbidden to use corrosive solvents or hard objects to wipe the photovoltaic modules.

(2) Photovoltaic modules should be cleaned under irradiance less than 200W/m2. It is not advisable to use liquids with a large temperature difference with the modules to clean the modules.

(3) It is strictly forbidden to clean photovoltaic modules under weather conditions with wind speed greater than level 4, heavy rain or heavy snow.

2. Photovoltaic modules should be inspected regularly. If the following problems are found, the photovoltaic modules should be adjusted or replaced immediately:

(1) The photovoltaic module has broken glass, burnt backboard, or obvious color changes;

(2) There are bubbles in the photovoltaic module that form a communication channel between the module edge or any circuit;

(3) The photovoltaic module junction box is deformed, twisted, cracked or burned, and the terminal cannot be properly connected.

3. The live warning sign on the photovoltaic module must not be lost.

4. The maintenance of the bracket should comply with the following regulations:

(1) All welds and bracket connections should be firm and reliable.

(2) The anti-corrosion coating on the bracket surface should not crack or fall off. If it does, it should be repainted in time.

5. The operation and maintenance of household photovoltaic systems shall comply with the following regulations:

(1) Photovoltaic building materials and photovoltaic components shall be regularly inspected, cleaned, maintained and serviced by professionals. If the following problems are found, they shall be adjusted or replaced immediately:

A. Condensation, water ingress and failure of glass;

B. Glass cracking, including thermal cracking and spontaneous cracking of tempered glass;

C. Delamination of coated glass, resulting in loss of architectural beauty;

D. Loosening, cracking and damage of glass.

(2) The drainage system of photovoltaic building materials and photovoltaic components must be kept unobstructed and should be dredged regularly.

(3) Doors and windows using photovoltaic building materials or photovoltaic components shall be flexible to open and close, hardware shall not be functionally impaired or damaged, and mounting bolts or screws shall not be loose or fail.

(4) The sealants of photovoltaic building materials and photovoltaic components shall not be debonded, cracked or bubbling, and the sealing strips shall not fall off or be damaged. (5) The equipment (cleaning machines, hanging baskets, etc.) used for inspection, cleaning, maintenance, and repair of photovoltaic building materials and photovoltaic components must be sturdy, flexible and easy to operate, safe and reliable, and measures should be taken to prevent impact and damage to photovoltaic building materials and photovoltaic components.

(6) When cleaning photovoltaic building materials and photovoltaic components indoors, water is prohibited from flowing into fireproof partition materials and the electrical interfaces of components or arrays.

(7) When replacing the glass of concealed frame glass photovoltaic building materials and photovoltaic components, the entire component should be replaced with a component that has expired its curing period.

(II) Inverter

1. The operation and maintenance of the off gird solar inverter shall comply with the following provisions:

(1) The settings of the overcharge voltage and overdischarge voltage of the off gird solar inverter shall comply with the design requirements;

(2) The warning signs on the off gird solar inverter shall be complete and clear;

(3) The wiring terminals of the off gird solar inverter shall not be loose or corroded;

(4) The specifications of the high-voltage DC fuse in the inverter shall comply with the design requirements;

(5) The insulation resistance of the positive pole to ground, the negative pole to ground, and the positive and negative poles of the DC output busbar shall be greater than 2 megohms;

(III) Grounding and lightning protection system

(1) The connection between the photovoltaic grounding system and the building structure steel bars shall be reliable.

(2) The connection between the photovoltaic modules, brackets, cable metal armor and the roof metal grounding grid shall be reliable.

(3) The grounding resistance of the grounding wire shared by the photovoltaic array and the lightning protection system shall comply with relevant regulations.

(4) The overvoltage protection device between the grounding wire of the photovoltaic array monitoring, control system, power regulation equipment and the lightning protection system shall be effective, and its grounding resistance shall comply with relevant regulations. (5) The photovoltaic array lightning protection device should be effective and should be checked in time before and after the thunderstorm season.

(IV) Line

1. The following items should be noted when maintaining the photovoltaic system cable:

(1) The cable should not be operated under overload conditions, and the lead sheath of the cable should not swell or crack;

(2) The cable should be sealed at the entrance and exit of the equipment, and there should be no holes with a diameter greater than 10mm. (3) In the part where the cable exerts too much pressure or tension on the equipment casing, the cable support point should be intact: (4) The cable protection steel pipe mouth should not have perforations, cracks or significant unevenness, and the inner wall should be smooth; the metal cable pipe should not be severely rusted; there should be no burrs, hard objects or garbage. If there are burrs, they should be filed smooth and wrapped with cable jacket and tied tightly: (5) The accumulation and garbage in the outdoor cable well should be cleaned in time: if the cable sheath is damaged, it should be processed. (6) When inspecting the indoor cable trench, prevent damage to the cable; ensure that the bracket is grounded and the heat dissipation in the trench is good. :

(7) The stakes along the direct buried cable line should be intact: No excavation of the ground near the path: Ensure that there are no heavy objects, building materials and temporary facilities piled on the ground along the path, and no corrosive substances are discharged: Ensure that the outdoor exposed ground cable protection facilities are intact:

(8) Ensure that the cover of the cable trench or cable well is intact; there should be no water or debris in the trench; ensure that the brackets in the trench are firm and free of rust and looseness; the armored cable sheath and armor should not be severely rusted:

(9) For multiple cables laid in parallel, the current distribution and the temperature of the cable sheath should be checked to prevent the cable connection points from being burned due to poor contact.

(10) Ensure that the cable terminal is well grounded, the insulation sleeve is intact, clean, and free of flashover discharge marks: Ensure that the cable phase color is obvious.

(11) Metal cable trays and their brackets and metal cable conduits for inlet or outlet must be grounded. (12) (PE) or zero connection (PEN) is reliable: the grounding wire should be reliably connected between the bridges.

(13) The fireproof sealing at the bridge wall should be tight and not fall off.

(14) Ensure that the bolts between the bridge and the bracket and the bolts of the bridge connecting plate are fixed well.